Process capability analysis

processCapability.RdComputes process capability indices for a 'qcc' object of type "xbar" and plot the histogram.

Usage

processCapability(object, spec.limits, target,

std.dev, nsigmas,

confidence.level = 0.95, ...)

# S3 method for class 'processCapability'

print(x, digits = getOption("digits"), ...)

# S3 method for class 'processCapability'

plot(x,

add.stats = qcc.options("add.stats"),

breaks = nclass.hist,

fill = adjustcolor(qcc.options("zones")$fill, alpha.f = 0.5),

color = "white", title, xlab,

digits = getOption("digits"), ...)Arguments

- object

a

'qcc'object of type"xbar"- spec.limits

a two-values vector specifying the lower and upper specification limits. For one-sided specification limits, the value of the missing limit must be set to

NA.- target

a value specifying the target of the process. If missing the value from the

'qcc'object is used if notNULL, otherwise the target is set at the middle value between specification limits.- std.dev

a value specifying the within-group standard deviation. If not provided is taken from the

'qcc'object.- nsigmas

a numeric value specifying the number of sigmas to use. If not provided is taken from the

'qcc'object.- confidence.level

a numeric value between 0 and 1 specifying the level to use for computing confidence intervals.

- x

an object of class

'processCapability'.- add.stats

a logical value indicating whether statistics and capability indices should be added at the bottom of the chart.

- breaks

a value or a function used to select the number of bins in a histogram. See the help for

nclass.scottfor more details.- fill, color

values specifying the colour of the filled area and the border used for drawing the histogram.

- title

a character string specifying the plot title. Set

title = NULLto remove the title.- xlab

a character string specifying the label for the x-axis.

- digits

the number of significant digits to use.

- ...

catches further ignored arguments.

Details

This function calculates confidence limits for \(C_p\) using the method described by Chou et al. (1990). Approximate confidence limits for \(C_{pl}\), \(C_{pu}\) and \(C_{pk}\) are computed using the method in Bissell (1990). Confidence limits for \(C_{pm}\) are based on the method of Boyles (1991); this method is approximate and it assumes that the target is midway between the specification limits.

Value

Invisibly returns a list with components:

- nobs

number of observations

- center

center

- std.dev

standard deviation

- target

target

- spec.limits

a vector of values giving the lower specification limit (LSL) and the upper specification limit (USL)

- indices

a matrix of capability indices (\(C_p\), \(C_{pl}\), \(C_{pu}\), \(C_{pk}\), \(C_{pm}\)) and the corresponding confidence limits.

- exp

a vector of values giving the expected fraction, based on a normal approximation, of the observations less than LSL and greater than USL.

- obs

a vector of values giving the fraction of observations less than LSL and greater than USL.

References

Bissell, A.F. (1990) How reliable is your capability index?, Applied Statistics, 39, 331-340.

Boyles, R.A. (1991) The Taguchi capability index, Journal of Quality Technology, 23, 107-126.

Chou, Y., Owen D.B. and Borrego S.A. (1990) Lower Confidence Limits on Process Capability Indices, Journal of Quality Technology, 22, 223-229.

Montgomery, D.C. (2013) Introduction to Statistical Quality Control, 7th ed. New York: John Wiley & Sons.

Wetherill, G.B. and Brown, D.W. (1991) Statistical Process Control. New York: Chapman & Hall.

Examples

data(pistonrings)

diameter = qccGroups(data = pistonrings, diameter, sample)

q = qcc(diameter[1:25,], type="xbar", nsigmas=3)

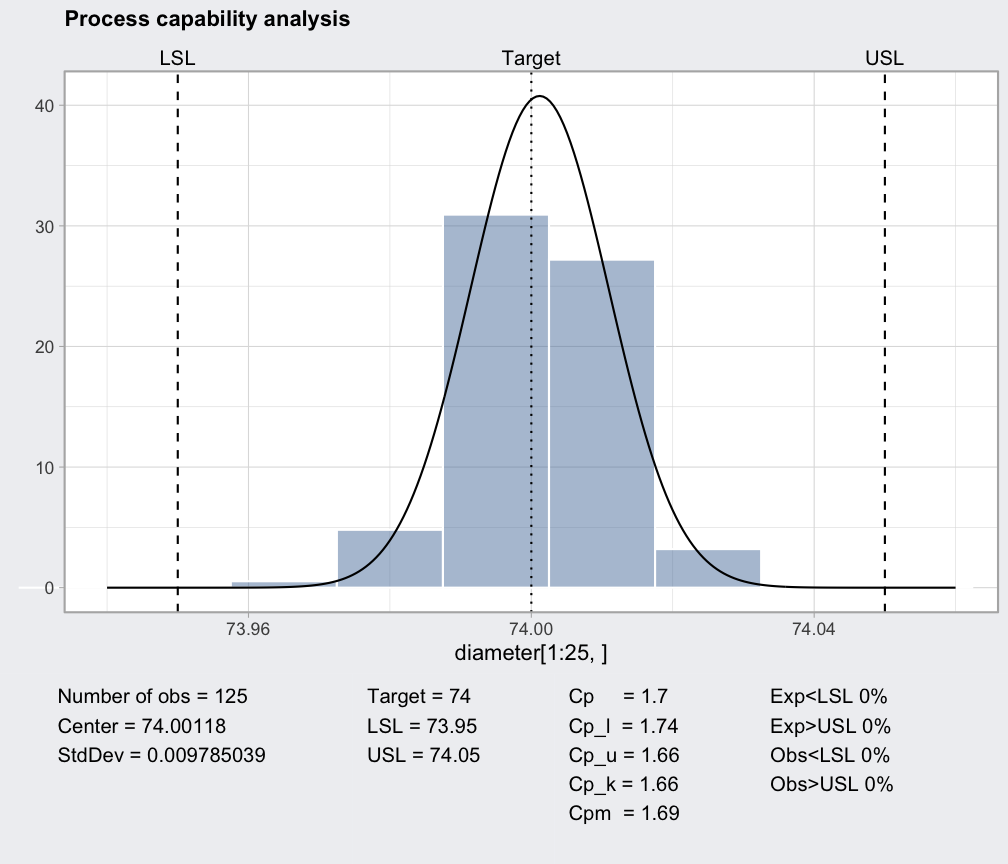

pc = processCapability(q, spec.limits=c(73.95,74.05))

pc

#> ── Process Capability Analysis ───────────────────

#>

#> Number of obs = 125 Target = 74

#> Center = 74.00118 LSL = 73.95

#> StdDev = 0.009785039 USL = 74.05

#>

#> Capability indices Value 2.5% 97.5%

#> Cp 1.70 1.49 1.91

#> Cp_l 1.74 1.55 1.93

#> Cp_u 1.66 1.48 1.84

#> Cp_k 1.66 1.45 1.88

#> Cpm 1.69 1.48 1.90

#>

#> Exp<LSL 0% Obs<LSL 0%

#> Exp>USL 0% Obs>USL 0%

plot(pc)

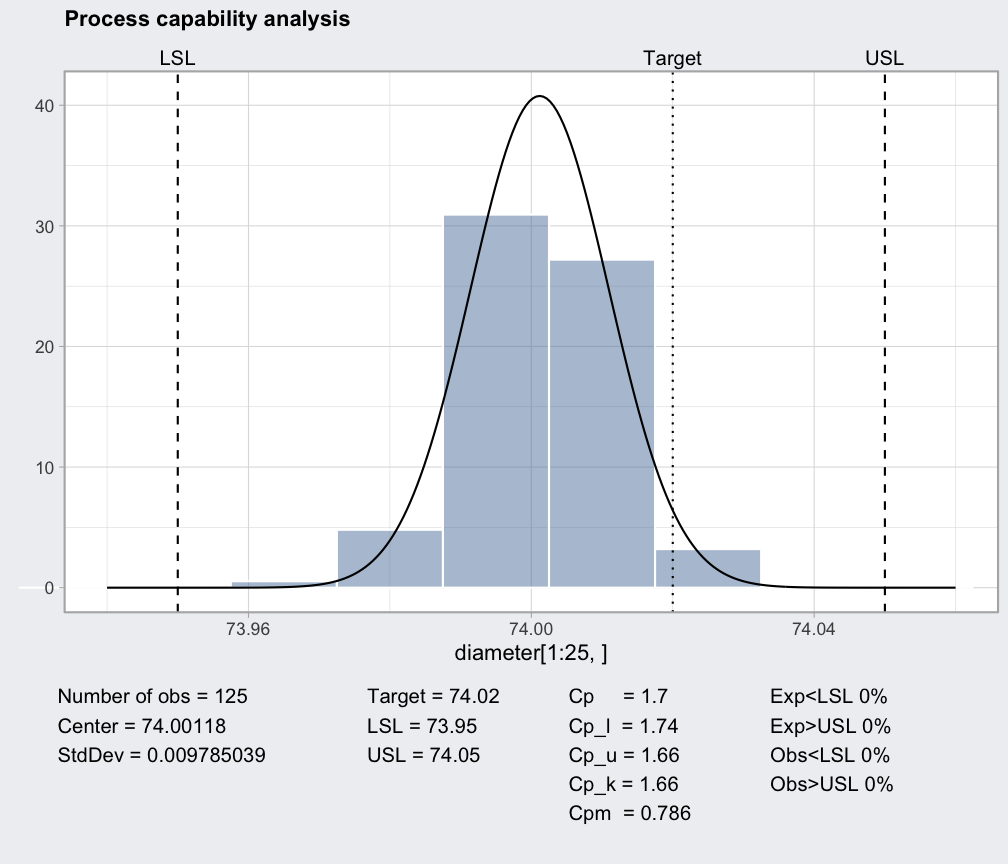

plot(processCapability(q, spec.limits=c(73.95,74.05), target=74.02))

plot(processCapability(q, spec.limits=c(73.95,74.05), target=74.02))

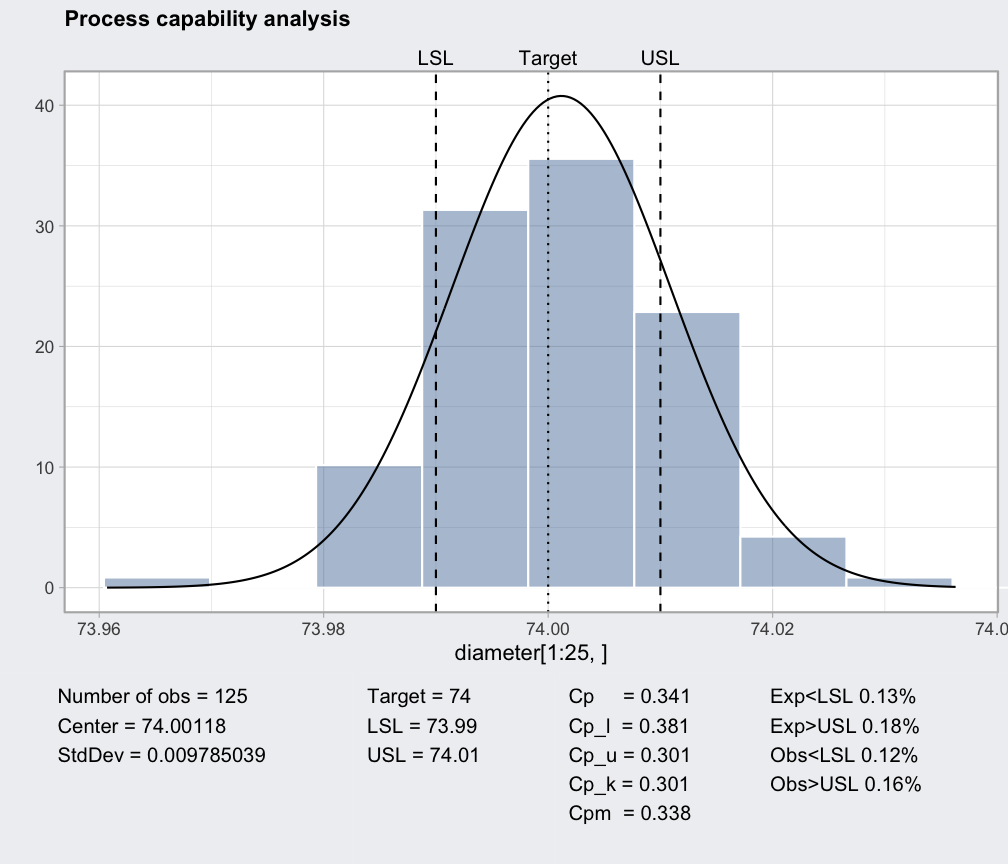

plot(processCapability(q, spec.limits=c(73.99,74.01)))

plot(processCapability(q, spec.limits=c(73.99,74.01)))

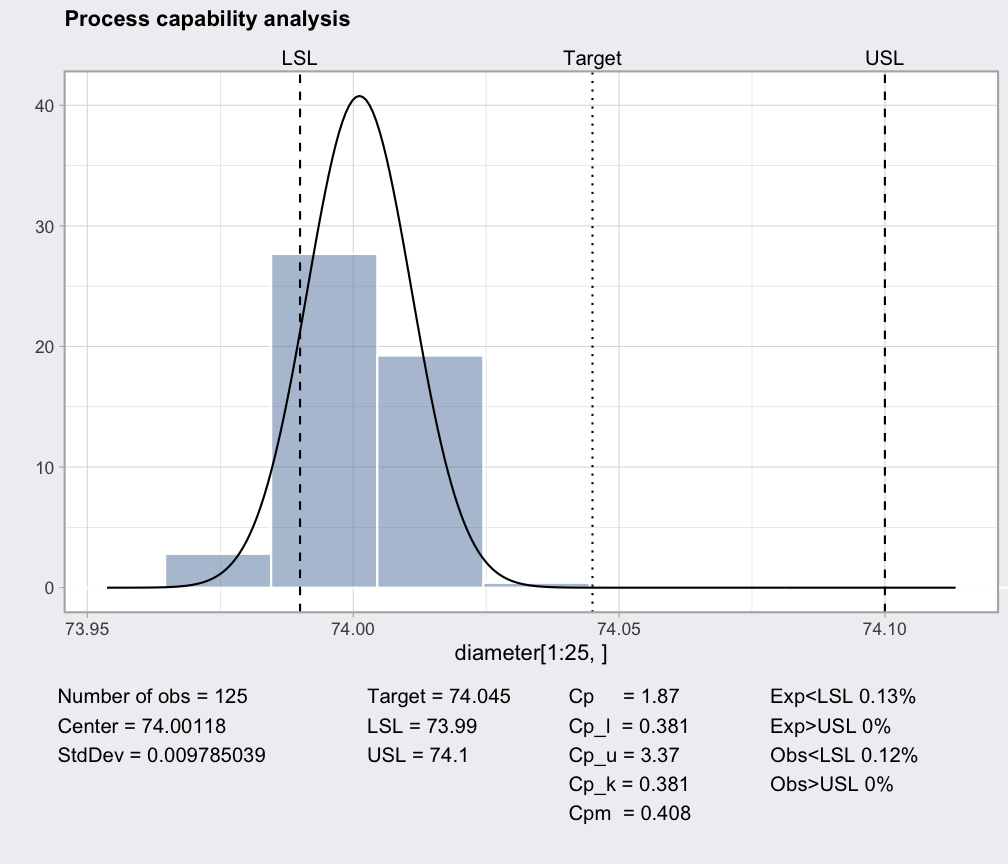

plot(processCapability(q, spec.limits = c(73.99, 74.1)))

plot(processCapability(q, spec.limits = c(73.99, 74.1)))