Statistics used in computing and drawing a Shewhart xbar chart for one-at-time data

stats.xbar.one.RdThese functions are used to compute statistics required by the xbar chart for one-at-time data.

Usage

stats.xbar.one(data, sizes)

sd.xbar.one(data, sizes, std.dev = c("MR", "SD"), r = 2, ...)

limits.xbar.one(center, std.dev, sizes, nsigmas = NULL, conf = NULL)Arguments

- data

the observed data values

- center

sample/group center statistic.

- sizes

samples sizes. Not needed,

size = 1is used.- r

number of successive pairs of observations for computing the standard deviation based on moving ranges of r points.

- std.dev

within group standard deviation. Optional for

sd.xbar.onefunction, required forlimits.xbar.one. See details.- nsigmas

a numeric value specifying the number of sigmas to use for computing control limits. It is ignored when the

confargument is provided.- conf

a numeric value in \((0,1)\) specifying the confidence level to use for computing control limits.

- ...

catches further ignored arguments.

Details

Methods available for estimating the process standard deviation:

"MR"= moving range: this is estimate is based on the scaled mean of moving ranges"SD"= sample standard deviation: this estimate is defined assd(x)/cd(n), wherenis the number of individual measurements ofx.

Value

The function stats.xbar.one returns a list with components statistics and center.

The function sd.xbar.one returns std.dev the standard deviation of the statistic charted.

The function limits.xbar.one returns a matrix with lower and upper control limits.

References

Montgomery, D.C. (2013) Introduction to Statistical Quality Control, 7th ed. New York: John Wiley & Sons.

Ryan, T. P. (2011), Statistical Methods for Quality Improvement, 3rd ed. New York: John Wiley & Sons, Inc.

Wetherill, G.B. and Brown, D.W. (1991) Statistical Process Control. New York: Chapman & Hall.

Examples

# Water content of antifreeze data (Wetherill and Brown, 1991, p. 120)

x = c(2.23, 2.53, 2.62, 2.63, 2.58, 2.44, 2.49, 2.34, 2.95, 2.54, 2.60, 2.45,

2.17, 2.58, 2.57, 2.44, 2.38, 2.23, 2.23, 2.54, 2.66, 2.84, 2.81, 2.39,

2.56, 2.70, 3.00, 2.81, 2.77, 2.89, 2.54, 2.98, 2.35, 2.53)

# the Shewhart control chart for one-at-time data

# 1) using MR (default)

qcc(x, type="xbar.one", data.name="Water content (in ppm) of batches of antifreeze")

#> ── Quality Control Chart ─────────────────────────

#>

#> Chart type = xbar.one

#> Data (phase I) = x

#> Number of groups = 34

#> Group sample size = 1

#> Center of group statistics = 2.569706

#> Standard deviation = 0.1794541

#>

#> Control limits at nsigmas = 3

#> LCL UCL

#> 2.031344 3.108068

# 2) using SD

qcc(x, type="xbar.one", std.dev = "SD", data.name="Water content (in ppm) of batches of antifreeze")

#> ── Quality Control Chart ─────────────────────────

#>

#> Chart type = xbar.one

#> Data (phase I) = x

#> Number of groups = 34

#> Group sample size = 1

#> Center of group statistics = 2.569706

#> Standard deviation = 0.2216795

#>

#> Control limits at nsigmas = 3

#> LCL UCL

#> 1.904667 3.234744

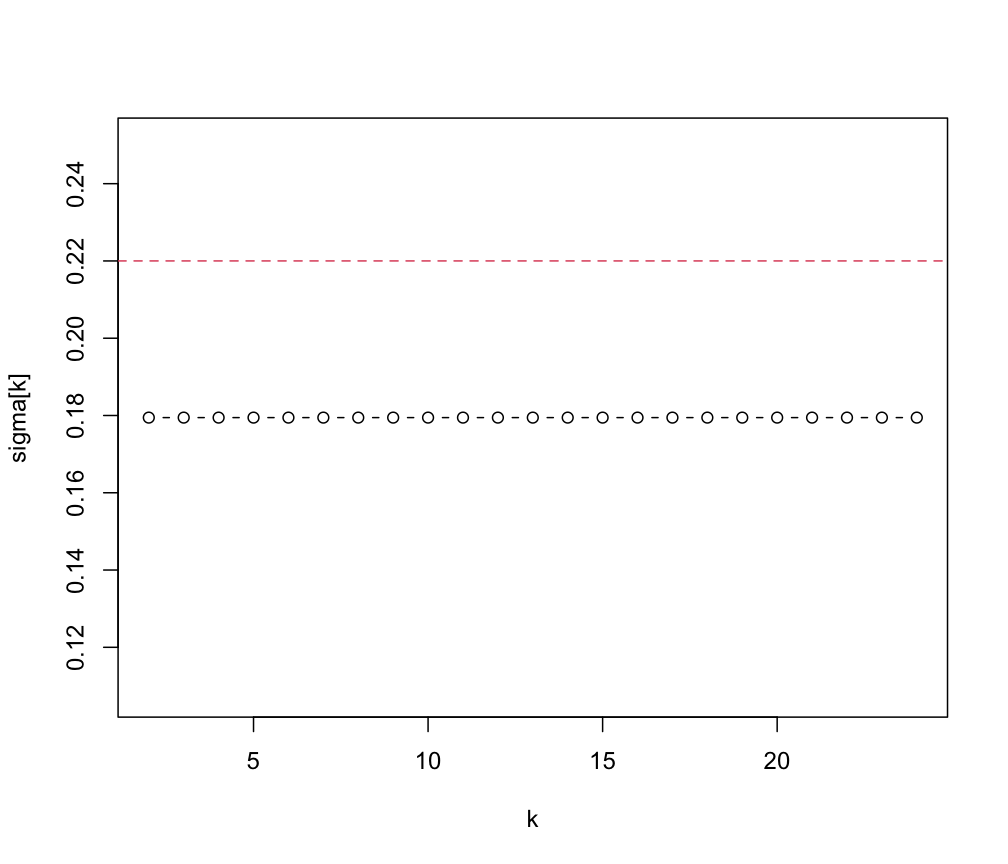

# "as the size increases further, we would expect sigma-hat to settle down

# at a value close to the overall sigma-hat" (Wetherill and Brown, 1991,

# p. 121)

sigma = NA

k = 2:24

for (j in k)

sigma[j] = sd.xbar.one(x, k=j)

plot(k, sigma[k], type="b") # plot estimates of sigma for

abline(h=sd(x), col=2, lty=2) # different values of k